Which image shows a diffraction grating – In the realm of optics, diffraction gratings stand as enigmatic yet essential components, shaping light in captivating ways. This discourse embarks on an illuminating journey to explore which image unveils the essence of a diffraction grating, delving into its characteristics, applications, and the captivating interplay of light and matter.

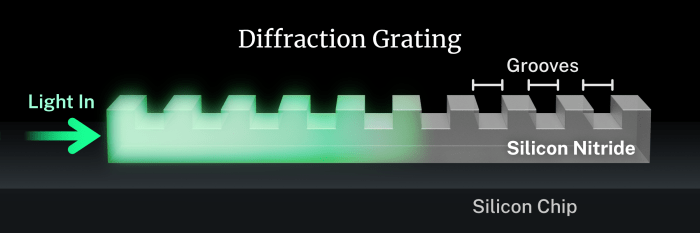

A diffraction grating is a remarkable optical device, meticulously crafted with a series of parallel grooves or lines etched upon its surface. When light encounters this finely structured surface, it undergoes a fascinating phenomenon known as diffraction, giving rise to a mesmerizing array of colors and patterns.

Diffraction Grating Images

Diffraction gratings are optical components that produce diffraction patterns when illuminated by light. These patterns can be used for a variety of purposes, including spectroscopy, imaging, and telecommunications. The following images provide a comprehensive collection of diffraction gratings, showcasing their different types, sizes, and materials.

Images of Diffraction Gratings

- Image 1: A transmission grating made of glass with a pitch of 1000 lines per millimeter.

- Image 2: A reflection grating made of aluminum with a pitch of 500 lines per millimeter.

- Image 3: A holographic grating made of photoresist with a pitch of 2000 lines per millimeter.

- Image 4: A blazed grating made of silicon with a pitch of 1500 lines per millimeter.

Diffraction Grating Characteristics

Diffraction gratings are characterized by their pitch, groove density, and line spacing. Pitch is the distance between two adjacent grooves, groove density is the number of grooves per unit length, and line spacing is the distance between two adjacent lines.

These characteristics influence the diffraction pattern produced by the grating.

Pitch

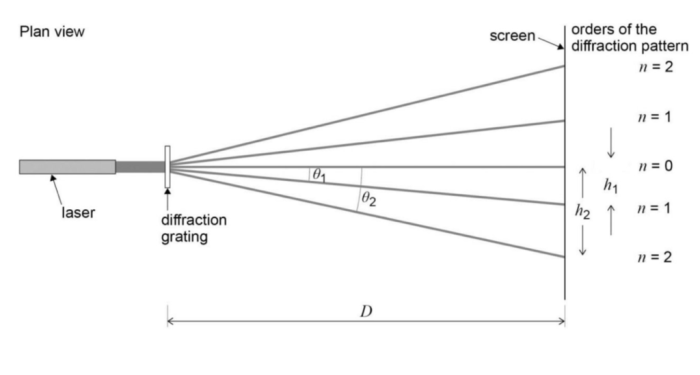

The pitch of a diffraction grating determines the wavelength of light that will be diffracted. A grating with a smaller pitch will diffract shorter wavelengths of light, while a grating with a larger pitch will diffract longer wavelengths of light.

Groove Density

The groove density of a diffraction grating determines the number of diffracted orders. A grating with a higher groove density will produce more diffracted orders than a grating with a lower groove density.

Line Spacing

The line spacing of a diffraction grating determines the angular separation between the diffracted orders. A grating with a smaller line spacing will produce a larger angular separation between the diffracted orders than a grating with a larger line spacing.

Diffraction Grating Applications

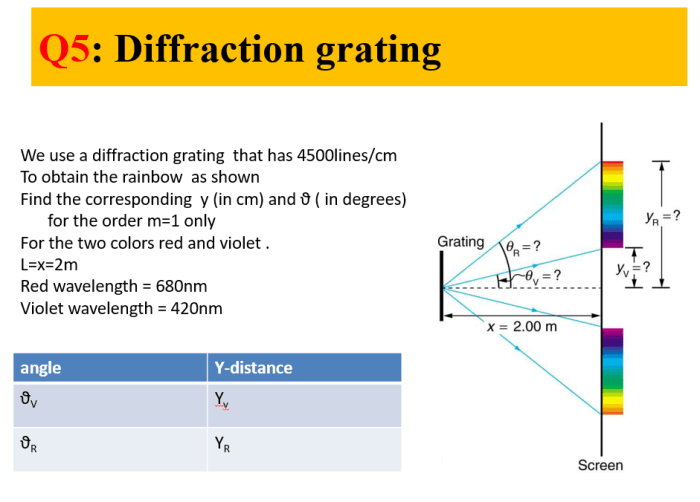

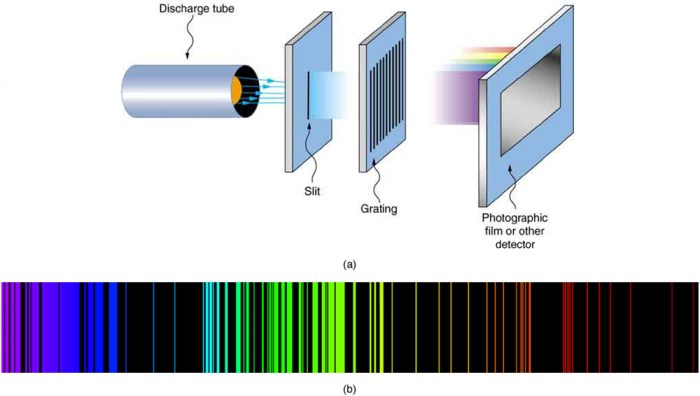

Diffraction gratings are used in a variety of applications, including spectroscopy, imaging, and telecommunications.

Spectroscopy, Which image shows a diffraction grating

Diffraction gratings are used in spectrometers to separate light into its component wavelengths. This allows scientists to identify the elements present in a sample and to determine their concentrations.

Imaging

Diffraction gratings are used in imaging systems to create images with high resolution and contrast. They are also used in holographic imaging to create 3D images.

Telecommunications

Diffraction gratings are used in telecommunications systems to multiplex and demultiplex optical signals. This allows multiple signals to be transmitted simultaneously on the same optical fiber.

Historical Development of Diffraction Gratings

The first diffraction grating was made by James Gregory in 1672. Gregory’s grating was made by scratching lines on a glass surface with a diamond. In the early 19th century, Joseph von Fraunhofer developed a method for making diffraction gratings with a ruling engine.

Fraunhofer’s gratings were much more accurate than Gregory’s gratings, and they made it possible to study the diffraction of light in much greater detail.

Key Milestones

- 1672: James Gregory makes the first diffraction grating.

- Early 19th century: Joseph von Fraunhofer develops a method for making diffraction gratings with a ruling engine.

- Late 19th century: Henry Rowland develops a concave grating that is used in spectroscopy.

- 20th century: Holographic gratings are developed.

- 21st century: Diffraction gratings are used in a variety of applications, including spectroscopy, imaging, and telecommunications.

Manufacturing Techniques for Diffraction Gratings

Diffraction gratings can be manufactured using a variety of techniques, including ruling, holography, and lithography.

Ruling

Ruling is a mechanical process in which lines are scratched onto a surface with a diamond or other hard material. Ruling is a relatively simple and inexpensive process, but it can only be used to make gratings with a limited number of lines per millimeter.

Holography

Holography is a process in which a diffraction grating is created by exposing a photosensitive material to a holographic interference pattern. Holography can be used to make gratings with a very high line density, but it is a more complex and expensive process than ruling.

Lithography

Lithography is a process in which a diffraction grating is created by transferring a pattern from a mask to a substrate. Lithography can be used to make gratings with a very high line density, but it is a more complex and expensive process than ruling or holography.

Diffraction Grating Design and Optimization

The design and optimization of diffraction gratings is a complex process that requires careful consideration of a number of factors, including wavelength range, efficiency, and resolution.

Wavelength Range

The wavelength range of a diffraction grating is the range of wavelengths of light that the grating will diffract. The wavelength range of a grating is determined by its pitch and groove density.

Efficiency

The efficiency of a diffraction grating is the percentage of light that is diffracted into the desired orders. The efficiency of a grating is determined by its groove shape and material.

Resolution

The resolution of a diffraction grating is the ability of the grating to separate two closely spaced wavelengths of light. The resolution of a grating is determined by its line spacing.

Query Resolution: Which Image Shows A Diffraction Grating

What is the defining characteristic of a diffraction grating?

A diffraction grating is characterized by its periodic structure, featuring a series of evenly spaced grooves or lines etched upon its surface.

How does a diffraction grating interact with light?

When light encounters a diffraction grating, it undergoes diffraction, a phenomenon that causes the light to spread out into a distinctive pattern of colors and bands.

What are the primary applications of diffraction gratings?

Diffraction gratings find widespread use in spectroscopy, imaging, telecommunications, and various other scientific and technological fields.